bulldozer cutting edge end bit motor grader blade loader cutting edge

$50.00

| Keyword | cutting edge/ Motor grader blade/ End bit / bulldozer cutting edge |

| Material | carbon steel, 16Mn, 35MnB |

| Color | Black,Yellow,Grey |

| Technoloy | Forging casting |

| Surface Hardness | Carbon HRC280-320HB Boron HRC440-520HB |

| Process | Heat treatment |

| Certification | ISO9001-2008 |

| Packing | Plywood pallet |

| Delivery Time | Within 15 days after order confirmed |

| Condition | New |

| Payment | T/T or western union or other |

The Boron type of GET has superior mechanical properties with much higher resistance to wear and abrasion due to the nature of chemical composition. As a result,the lifespan of Boron type of GET will be at least twice that of carbon steel.Thus,the cost savings on downtime,labour charges and plow bolts and nuts are tremendous.

Mechail Proper with Heat Treatment:

The Boron type of GET has superior mechanical properties with much higher resistance to wear and abrasion due to the nature of chemical composition. As a result,the lifespan of Boron type of GET will be at least twice that of carbon steel.Thus,the cost savings on downtime,labour charges and plow bolts and nuts are tremendous.

Mechail Proper with Heat Treatment:

| Element | Boron Steel | Carbon Steel |

| Hardness | 440-520HB | 280-320HB |

| Yielding Point | 1440N/mm2 | 600Re-N/mm2 |

| Breaking Point | 1674N/mm2 | 1030RM/N/mm2 |

| Elongation | 11% | 12% |

| Resilience at-20C | 51J | 6J |

The part numbers below are just for your reference, for more details, kindly contact us directly!

Cutting edge:12F-70-31251,12F-70-31261,130-70-41130,130-920-2180,144-70-11131,14X-71-11310,14Y-71-11210,154-70-11313,154-70-11314,154-81-11191/90,175-70-21115,175-70-26310,17A-71-11351,17M-71-21550,195-70-12492,195-71-11654,195-71-51120,198-72-11181,1U0295,1U4941,1U4943,1U4944,232-70-12143,4T2309,4T2315,4T2863,4T2867,4T2917,4T2921,4T2922,4T2948 ,4T2949

End bit:112-946-1510,11G-71-31170,13F-Z27-1572/82,140-70-11170/80,144-70-11180/70,144-70-11180/90,144-70-11260/50,150-70-21346/56,175-70-21126/36,175-71-22272/82,17M-71-21930/40,195-71-11173/11183,1U1545/46,

232-70-52190,234-70-12233,3G4282/5,3G7763/4,3G8283/4,3G8291/2,3G8293/4,3G8297/8,3G8301/2,3G8315/6,

3G8319/20,4T3045/6,4T4435/6,4T5407/8,4T6695,5J1279/80

Motor grader blade:5B5562,5B5564,5D9553,5D9554,5D9556,5D9557,5D9558,

5D9559,5D9561,5D9562,5D9731,5D9732,6G8623,7D11587D1576,2C3139,3G1626,3G1627,3G1628,

3G2165,3G2166,3G7965,3G7966,3G8016,4T2231,4T2233,4T2236,4T2237,4T2240,4T2242,4T2244,

4T2966,4T2967,4T2968,4T2969,4T2970,4T2971,4T3007,4T3032,4T3033,4T3034,4T3035,4T3036,4T3037,

4T3511,4T3512,4T6502

half arrow: 3048*254*30,4267*254*30,4267*254*40,3658*254*40,3048*254*40

Packing Details: Plywood pallet/Case

Size: L(1.2m)*W(1.2m)*H(0.8m)

Weight: Less than 1.5 tons

Mark: YSQ

Original: Made in china

RELATED PRODUCTS

Why Choose Us?

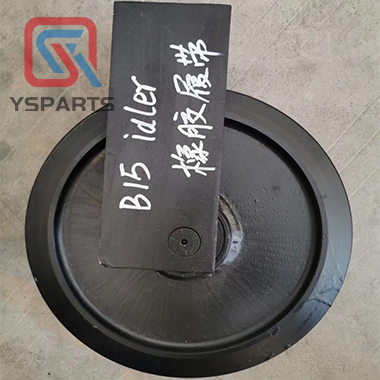

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions.

OEM part number guidance and maritime logistics guidance