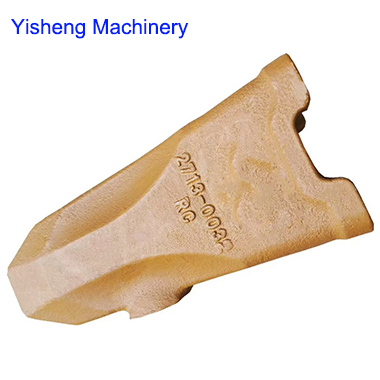

excavator bucket teeth doosan bucket tooth 2713-1219RC

$50.00

| Order(Moq): | 10pcs |

| Material: | Alloy steel |

| Hardness | HRC47-52( Bucket Teeth), HRC43-48(Adapter) |

| Payment: | T/T, L/C, D/P, Western Union |

| Origin: | China |

| Color: | Yellow,Black or Customized |

| Lead Time: | Within 20 days |

| Technique: | heat treatment with HQC |

| Condition: | new |

| Application: | Excavator |

Available part number for your reference as bleow, for more items, please kindly contact us directly.

| PART NO. | WEIGHT (KG) | DESCIPTION | BRAND | FAMILY/MODEL |

| 1U3201 | 1.45 | TEETH SHORT | CAT | J200 |

| 1U3202 | 1.35 | TEETH STANDARD LONG | CAT | J200 |

| 1U3202P | 1.4 | TEETH ROCK | CAT | J200 |

| 1U3202TL/9W8209 | 1.35 | TEETH TIGER | CAT | J200 |

| 1U3202WTL/135-8208 | 1.35 | TEETH TWIN TIGER | CAT | J200 |

| 1U3209 | 1.25 | TEETH PENETRATION | CAT | J200 |

| 1U3251 | 2.7 | TEETH ROCK | CAT | J250 |

| 1U3252 | 2.9 | TEETH STANDARD LONG | CAT | J250 |

| 1U3252TL/9W8259 | 2.7 | TEETH TIGER | CAT | J250 |

| 1U3252WTL/135-8258 | 3.5 | TEETH TWIN TIGER | CAT | J250 |

| 1U3252RC | 3.5 | TEETH ROCK CHISEL | CAT | J250 |

| 1U3301 | 4 | TEETH SHORT | CAT | J300 |

| 1U3302 | 4.3 | TEETH STANDARD LONG | CAT | J300 |

| 1U3302 | 4.7 | TEETH STANDARD LONG | CAT | J300 |

| 1U3302TL/9W8309 | 4.3 | TEETH TIGER | CAT | J300 |

| 1U3302WTL/135-9308 | 4.8 | TEETH TWIN TIGER | CAT | J300 |

| 1U3302RC | 4.9 | TEETH ROCK | CAT | J300 |

| 1U3302RC-2 | 4.8 | TEETH ROCK | CAT | J300 |

| 1U3302RCL | 4.95 | TEETH FISH SCALE | CAT | J300 |

| 1U3302R/9J4302 | 4.5 | TEETH ROCK | CAT | J300 |

| 1U3302SYL | 5.2 | TEETH SYL | CAT | J300 |

| 1U3351 | 5.5 | TEETH SHORT | CAT | J350 |

| 1U3352 | 5.6 | TEETH STANDARD LONG | CAT | J350 |

| 1U3352 | 5.8 | TEETH STANDARD LONG | CAT | J350 |

| 1U3352 | 6 | TEETH STANDARD LONG | CAT | J350 |

| 1U3352R/9J4352 | 6 | TEETH ROCK | CAT | J350 |

| 1U3352TL/9W2359 | 6 | TEETH TIGER | CAT | J350 |

| 1U3352WTL | 7 | TEETH TWIN TIGER | CAT | J350 |

| 1U3352RC | 7 | TEETH ROCK CHISEL | CAT | J350 |

| 1U3352RC | 8.2 | TEETH ROCK | CAT | J350 |

| 1U3352RCK | 6.5 | TEETH ROCK | CAT | J350 |

| 1U3352SYL | 7.8 | TEETH SYL | CAT | J350 |

| 1U3452 | 12.65 | TEETH STANDARD LONG | CAT | J460 |

| 1U3452SYL | 11.1 | TEETH SYL | CAT | J460 |

| 1U3452TL/9W8452TL/7T8459 | 13.5 | TEETH TIGER | CAT | J460 |

| 1U3452C | 15 | TEETH ROCK TEETH | CAT | J460 |

| 1U3452RC | 13.4 | TEETH ROCK | CAT | J460 |

| 1U3452RC | 15 | TEETH ROCK | CAT | J460 |

| 1U3552TL | 22.5 | TEETH | CAT | J550 |

| 1U3552RCL | 22.7 | TEETH FISH SCALE | CAT | J550 |

RELATED PRODUCTS

Why Choose Us?

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to avoid bending and breakage.

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions.

OEM part number guidance and maritime logistics guidance

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions.

OEM part number guidance and maritime logistics guidance