excavator track shoes track steel pad 800mm track plate shoe

$20.00

| Order(Moq): | 10pcs |

| Material: | 25MnB |

| Warranty | 6-12 months |

| Payment: | T/T, L/C, D/P, Western Union |

| Origin: | China |

| Color: | Yellow,Black or Customized |

| Lead Time: | Within 20 days |

| Technique: | Forging |

| Condition: | new |

| Application: | Excavator |

Our products track roller,carrier roller,idler,sprocket,track link for all kinds of types excavator and bulldozer undercarriage parts are of high quality and at reasonable prices, certified by ISO9001:2008, and specifically designed, engineered and manufactured under consistent quality control. We also make goods according to OEM requirements. Furthermore, we can produce new products according to customers' samples, designs and technical drawings.

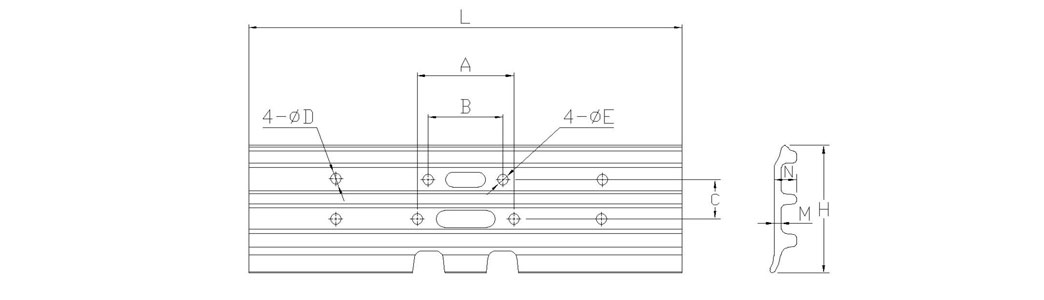

Main Parameters

| Suitable Model | Main Dimensions of Installation | ||||

| A | B | C | E | H | |

| PC300/EX300-5/EX350LC-5/ZAX300/SH330 | 178.4 | 140.4 | 76.2 | φ22.8 | 250 |

| EX400/EC460/PC300HD/PC400/EX400/PC360 | 184 | 146 | 76.2 | φ22.8 | 250 |

| PC400-5/6/PC300HD-3/5/PC360LC-1/3/5 | 184 | 146 | 76.2 | φ24.6 | 247 |

| E330/SK300/SK400 | 190 | 140 | 76.2 | φ23 | 250 |

| PC300-3/5/PC300-5/DH280/EX300-3/EX270 | 178.4 | 138.4 | 72.2 | φ20.5 | 236 |

| CAT325/E325ST | 179 | 129 | 72 | φ21.0 | 236 |

| DH220/EC210/R220/SK230/PC230/PC200-5/6 | 160.4 | 124.4 | 62 | φ20.5 | 219 |

| EX200-2/5/EX210/PC200-2/3/ZAX230/EX220 | 160.4 | 124.4 | 62 | φ18.5 | 219 |

| E200B/EL200B/E320C/SK200/SK230/SH200 | 155.57 | 119.57 | 69 | φ21.0 | 219 |

| EX100/ZX120/SX120/EX120/DH120/CAT312 | 108 | 108 | 60.4 | φ16.5 | 190 |

| PC100-5/6/PC120-5/6/PC130-6 | 102.4 | 86.4 | 57 | φ16.3 | 190 |

| EX200-1/R200 | 144.46 | 125.41 | 58.74 | φ16.3 | 190 |

| PC120-3 | 112.4 | 82.4 | 57 | φ14.5 | 165 |

| EC60-1/ECR88/EX60-2/3/EX75UR | 90 | 90 | 55 | φ14.5 | 165 |

| PC60-3/S50/D20/ZY65 | 99 | 72 | 43.4 | φ12.5 | 154 |

| CAT305/EX40/SY55-65 | 104 | 80 | 46 | φ12.5 | 154 |

| PC40-7/PC45/PC50-7/8/SK40 | 94 | 64 | 47 | φ12.2 | 154 |

The models above are just for reference, we can’t list all models here. we can supply more products as your requirements. Please feel free to send us your inquiry.

RELATED PRODUCTS

Why Choose Us?

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to avoid bending and breakage.

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions.

OEM part number guidance and maritime logistics guidance

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions.

OEM part number guidance and maritime logistics guidance