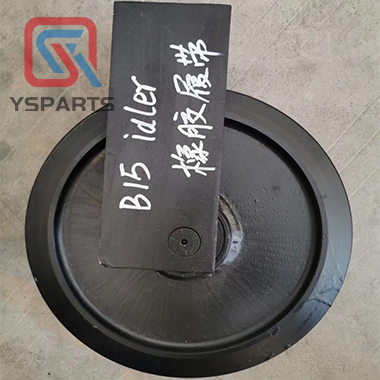

Mitsubishi BD2G bulldozer front idler

$120.00

| Part name | front idler/ idler roller/ idler wheel |

| Material | 40Mn2,50Mn/35SiMn |

| Finish | Smooth |

| Colors | Black or yellow |

| Technique | Forging casting |

| Surface Hardness | HRC52-58 |

| Warranty time | 2000~3000 hours |

| Certification | ISO9001-2008 |

| Delivery Time | Within 15 days after contract established |

| Packing | standard exported pallet or box |

| Condition | New |

| Payment | T/T or western union or other |

RELATED PRODUCTS

Why Choose Us?

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to avoid bending and breakage.

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions.

OEM part number guidance and maritime logistics guidance

Our roller shell is made of high quality alloy steel, through the whole heating quenching and tempering to increase the service life of supporting wheels.

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing to meet the needs of high-intensity operations.

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions.

OEM part number guidance and maritime logistics guidance